NEW

Completely new.

AND COMPLETELY FAMILIAR.

Update your B.I system now to the new software release B.I PROX3.

With PROX3 the things you do most often get a new look and become even easier.

New features ensure that you always get exactly the information you need.

PLANNING & PROJECT PLANNING

Together with the customer, we plan the special systems on the basis of the given, customer-side conditions and requirements for the system. We create a concept about the time and technical process of the project.

DESIGN & STYLING

The product design is developed specifically for each customer. All drawings and documents required for the subsequent production are prepared accordingly.

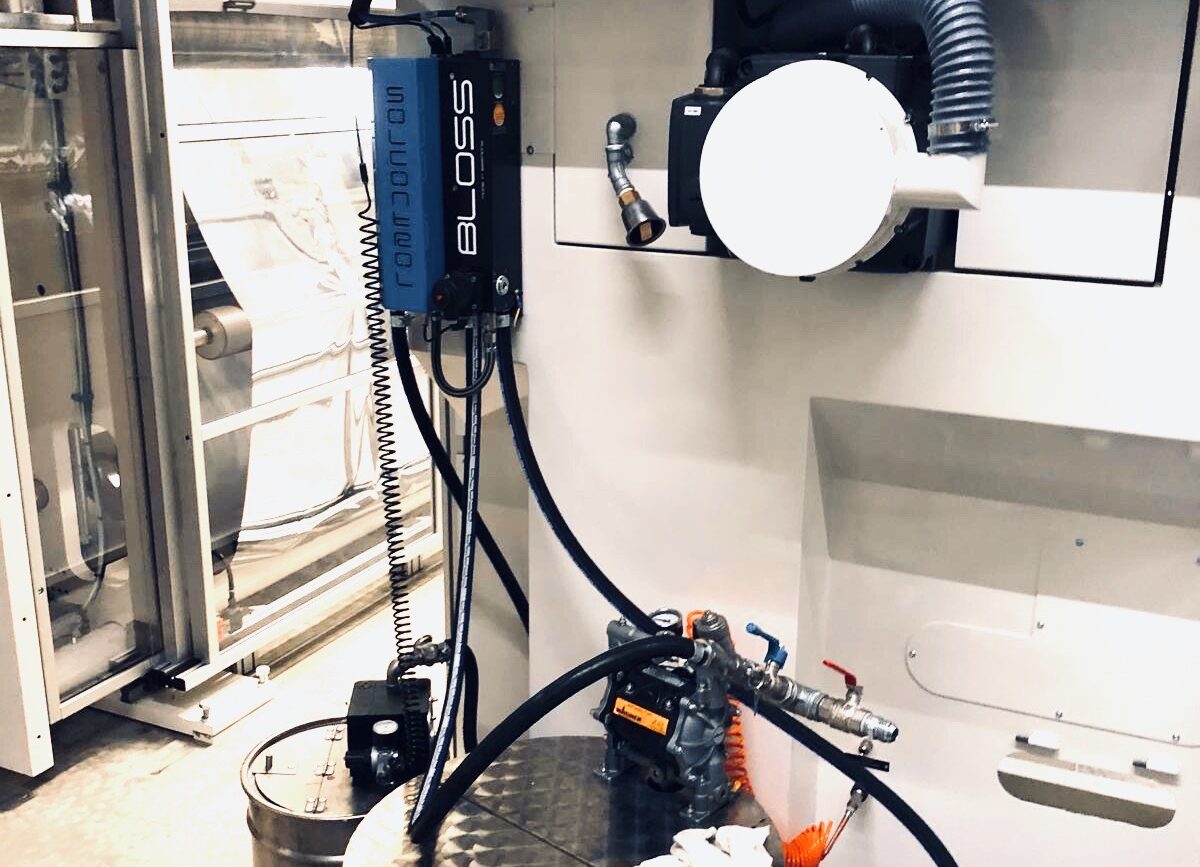

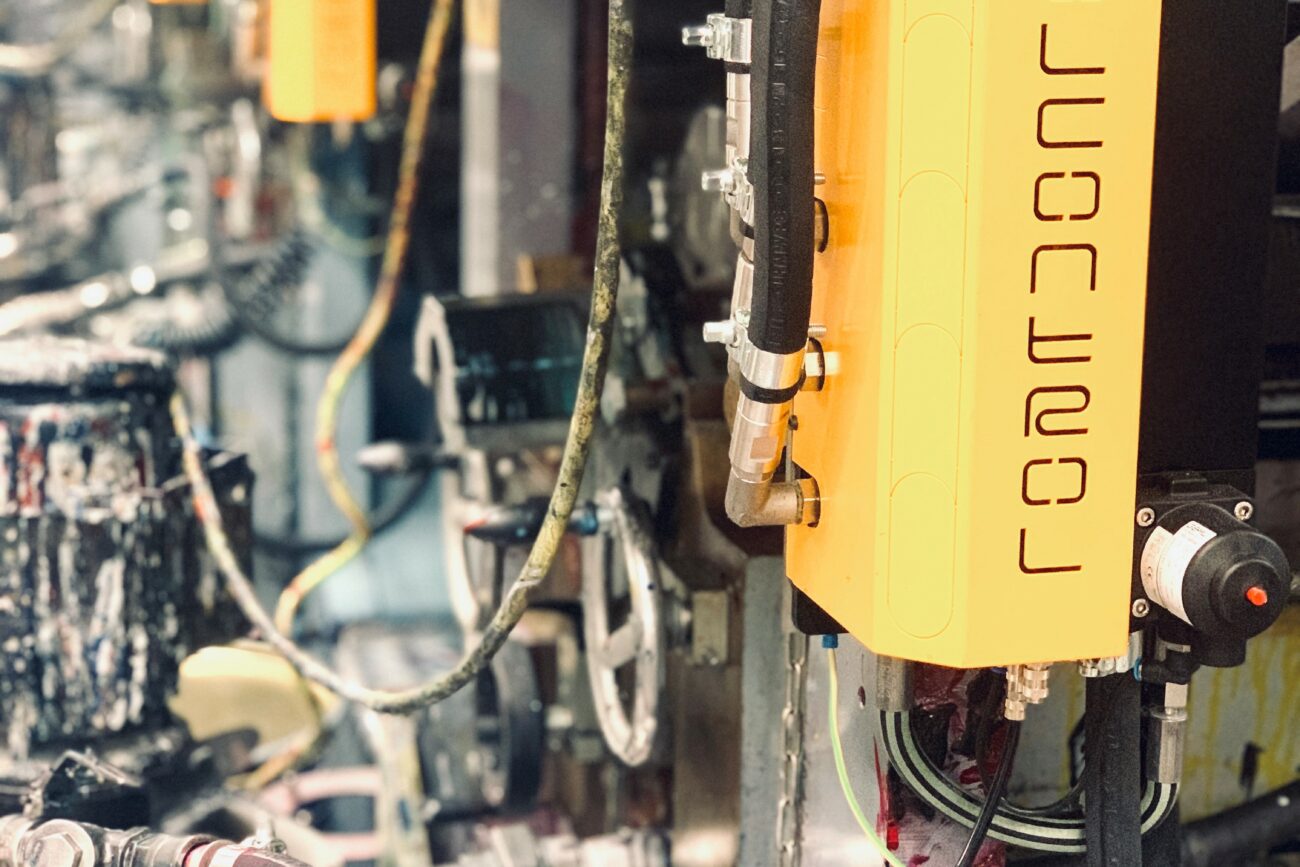

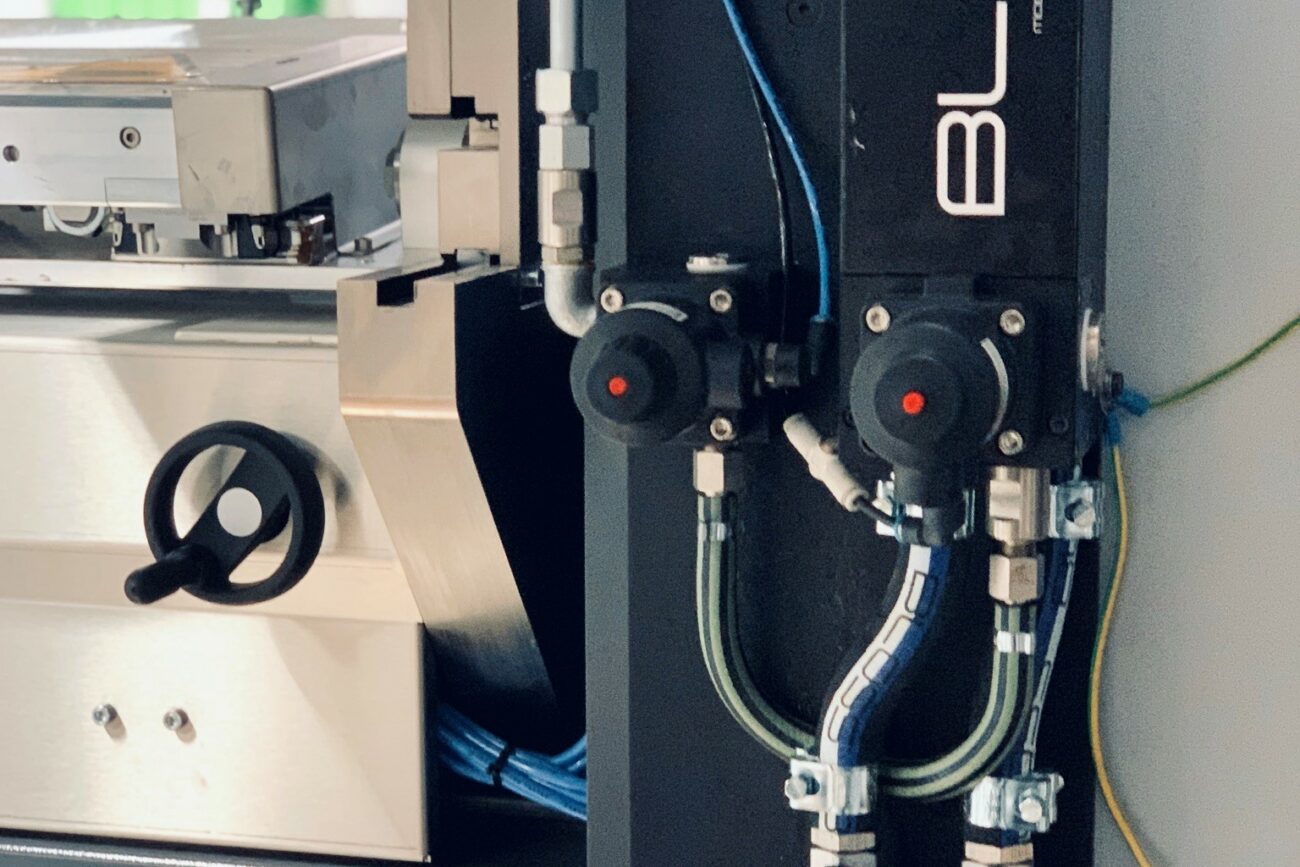

MANUFACTURING & MOUNTING

In our state-of-the-art machine park we manufacture the product, taking all our customers' technical and individual specifications into account. The assembly on site can be carried out by ourselves or, if requested, can also be performed by the customer himself in accordance with the assembly instructions.

SOFTWARE SOLUTIONS & APPLICATIONS

For an optimal performance and customized settings on the machine, we can also provide any software solution. The system's communication and automation may therefore be configured to match the customer's specific demands.

MACHINING & PROTOTYPES

We process aluminium, stainless steel or plastic on our state-of-the-art machines. We manufacture the product according to the customer's specifications and, due to our experienced staff's diligence, we are able to achieve high quality products.

SHEET METAL PROCESSING & LASER TECHNOLOGY

We also have the appropriate tools for cutting, milling, welding, bending, stamping or laser engraving. We process sheet metal in accordance with the customer's order, taking extreme caution and strictly following his specifications.

OUR QUALITY CONCEPT

In order to ensure our customers' long-lasting satisfaction, we have high quality standards for all our products. Every single product from our brands is produced, controlled and certified according to our high standards.

#PRODUCTSAFETY - We place the highest value on the consistently good quality of our products. Through regular maintenance and testing of our machinery, as well as constant training of our staff, we can guarantee a high level of product safety.

#RISKMANAGEMENT - Our company's risk management deals with all measures that are important for avoiding risks and reducing risks. In this way, the probability of a negative event can be kept as low as possible or, in the event that it should nevertheless occur, appropriate countermeasures can be taken as quickly as possible.

#PRODUCTREQUIREMENT - We determine and evaluate requirements for the product. These are, on the one hand, the individual requirements based on the needs of the customer and, on the other hand, the general requirements that are placed on the product according to the current state of the art.

#WARRANTY MANAGEMENT - Despite all due care, errors or defects can occur. So that the customer can be satisfied in the best possible way in the event of a complaint with a warranty claim, we are also equipped in the area of warranty management.

OUR PROJECTS

Learn more about our projects, experience us as a reliable special machine builder at your side and convince yourself of our know-how.

The aim of our work is to offer the perfect solution for the individual application purpose according to the wishes and requirements of our customers. Already in the early stages of product development, we support our customers in product design and the development of the plant concept that is optimally tailored to your needs.

We respond flexibly to local conditions and product expectations and can thus offer cross-industry solutions.

Through customized interfaces, we create communication and automation in a holistic concept. Our experienced team offers professional support from planning, design, manufacturing and assembly to commissioning. In doing so, we are constantly in close cooperation with the customer in order to be able to execute the project to the customer's fullest satisfaction.