Our brands

When you choose a product from our portfolio, you are choosing a high quality product that has been developed with the utmost care. Discover our selected brands.

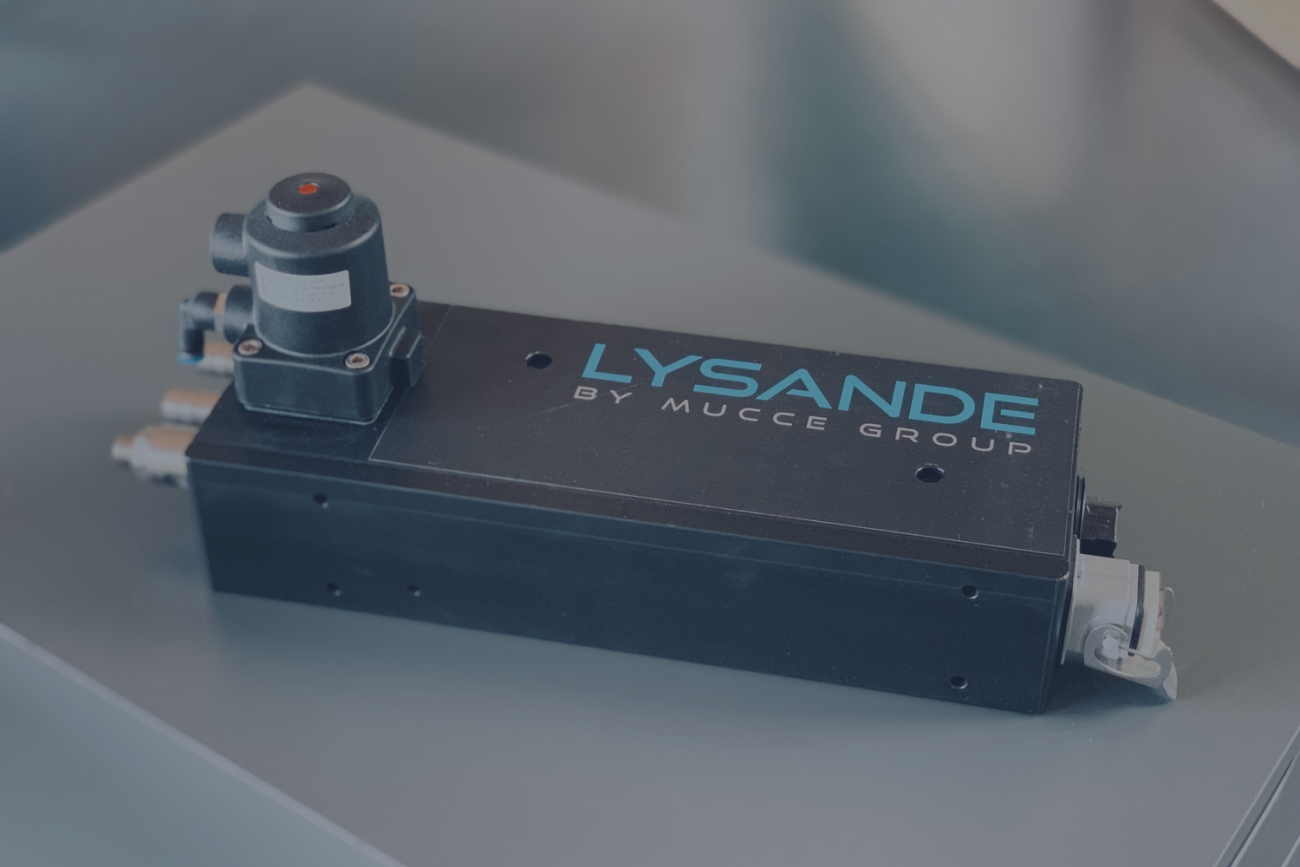

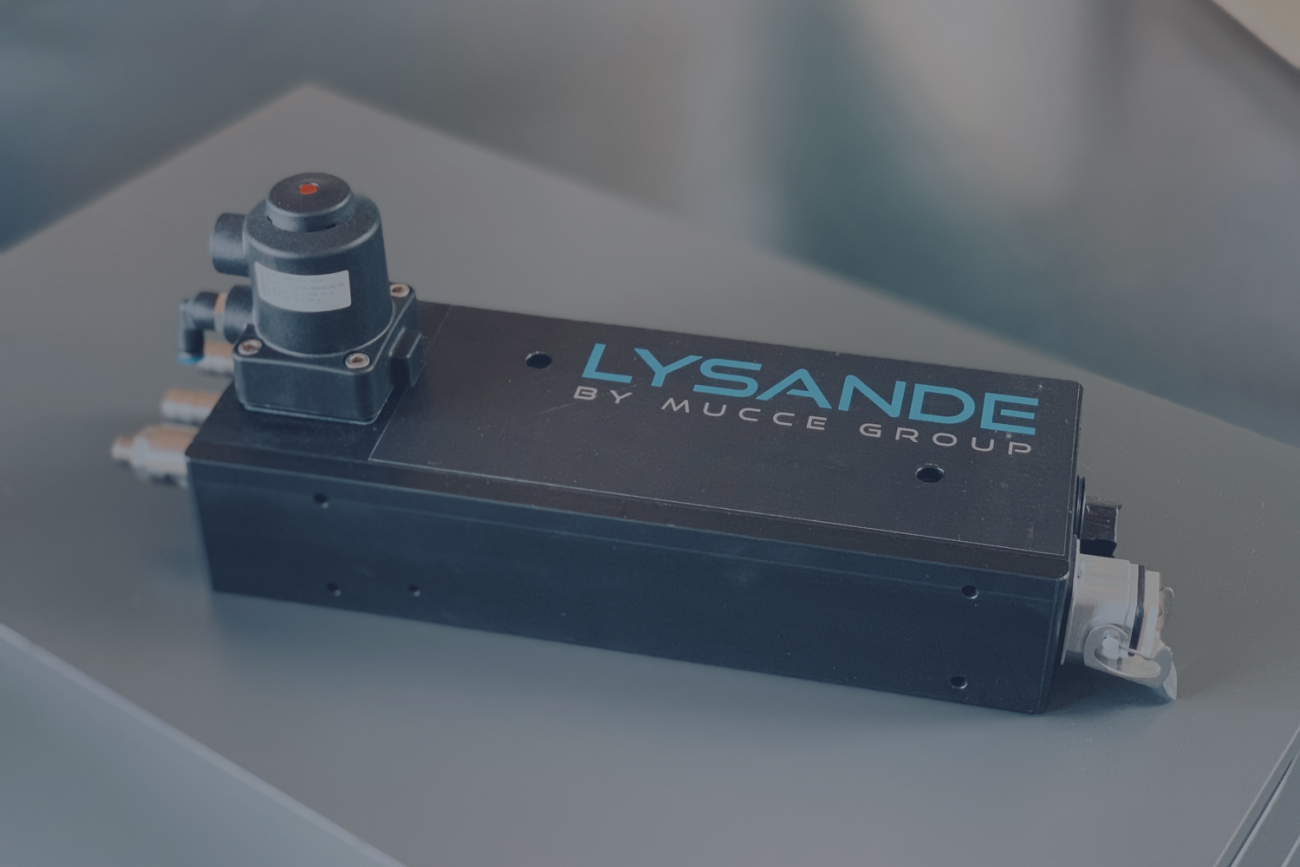

It can also be good, even if it's simple.

We also offer simple solutions for simple applications. Our aim here is to keep our customer's investments as low as possible, but still being able to provide a certified product. Let yourself be impressed and allow us to introduce you Lysande.

CLIENT

LYSANDE

YEAR

2018

SERVICES

Viscosity control system

VISIT WEBSITE

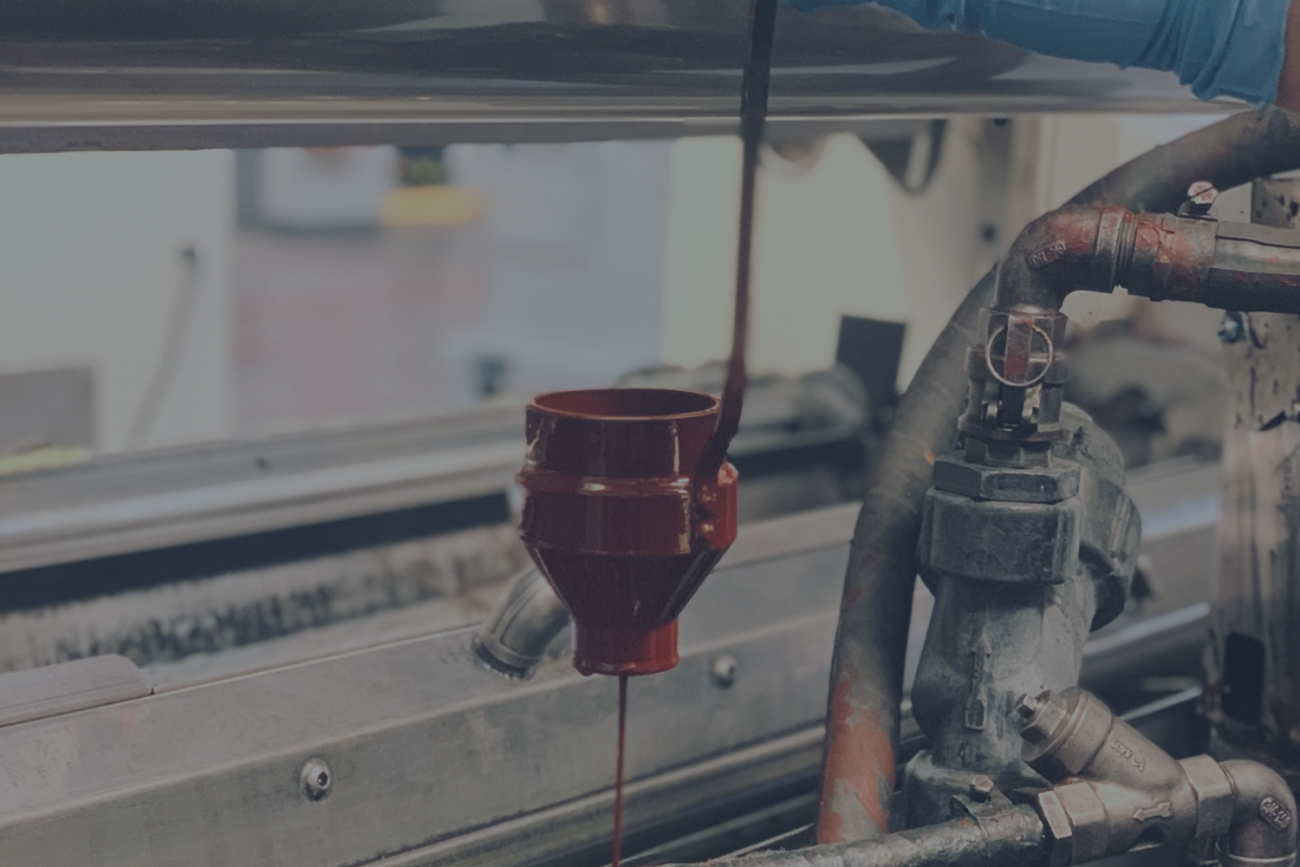

Precision is the passion for detail.

Bloss.Industries Original Parts stands for a modern and yet user-friendly concept. A wide range of application options, local conditions and software make it easier for our customers to choose the best of all media management systems. Let yourself be inspired by Bloss.Industries Original Parts' outstanding and innovative products.

CLIENT

BLOSS.INDUSTRIES

YEAR

2018

SERVICES

Ink / Lacquer ManagementInk / Lacquer Management

VISIT WEBSITE

Because we love our long-standing customers.

Even after so many years, we never let our customers down. Due to the high quality of our ink management systems, and even after an extended period of time, we are still able to provide spare parts through Bloss.Industries Classic Parts, without being economically unreasonable. The "classics", in particular, confirm us every day anew the exceptional durability of our products. We are looking forward to your inquiry.

CLIENT

BLOSS.INDUSTRIES

YEAR

2018

SERVICES

Ink / Lacquer ManagementInk / Lacquer Management

VISIT WEBSITE

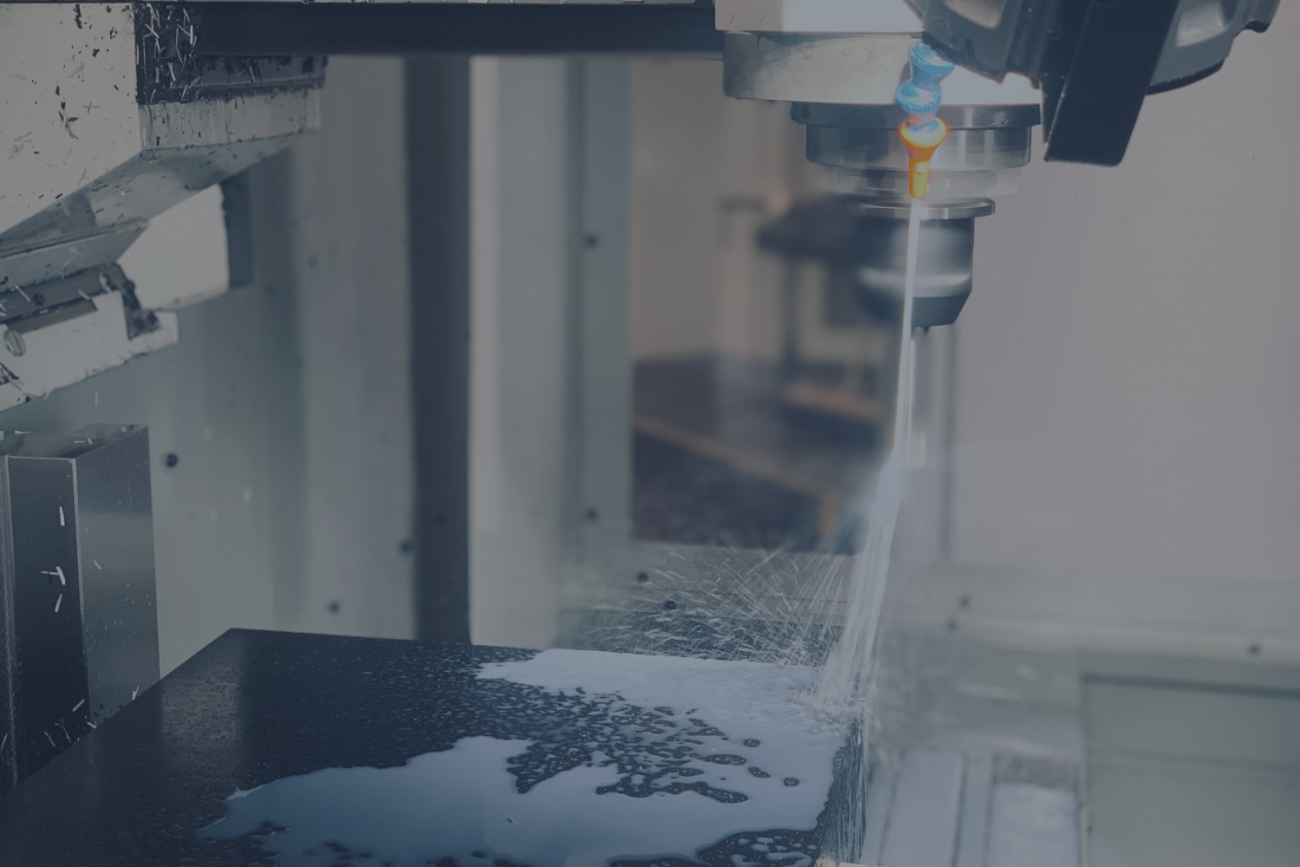

We'll take care of it.

Wambert stands for metal machining according to the customer's order. We machine, mill, weld, engrave, twist metal sheet, aluminium, stainless steel, plastics, metals and much more. Our certified specialists will plan, design and manufacture the product according to the customer's specifications. Are you interested? Please contact us.

CLIENT

WAMBERT

YEAR

2019

SERVICES

Machining

VISIT WEBSITE

The best ideas come to me when I imagine that I'm my own customer!

Our products

With our wide range of products, our focus is on always satisfying our customers, and to offer them a solution for each and every requirement.

Ink management systems

We plan, design and build complete ink management systems. Together with the customer, we adjust the system according to his individual specifications. With an ink management system we can reach the automation of the whole production process.

Coating Management Systems

We are also able to provide individual applications for coating machines. With our lacquer management systems, coating and lamination with water-based and 2-component lacquers can be monitored, controlled, automated and optimized.

Customized products

Even if our standard systems are not suitable for you, we can still offer you the appropriate solution. Our products are developed exclusively to match our customers' individual specifications and requirements.

Viscosity control

We manufacture accurate sensors designed to measure and control the viscosity of a variety of media. With the optimal viscosity, the medium consumption can be considerably reduced.

Density control

Our density control systems are an extension of the viscosity control systems. Similar to the viscosity control, the medium density is determined. However, it is much more accurate, has a higher frequency and resolution.

Solvent dispensing

Our solvent dispensing modules can be equipped with up to 6 solvents as standard. Customized solutions may even dispense a larger number of solvents.

Temperature control

Our temperature management module either cools or heats the medium up to the required temperature. The appropriate temperature is essential to obtain an optimal end result.

Ink Pump Systems

Our portfolio also includes pump systems to automatically transfer printing ink from the storage tank into the circulation tank.

Coating Dispensing Systems

Especially designed for the coating industry, we have developed high-precision systems to control accurately the correct dosage of lacquers and primers. Due to a special advanced technology, the use of our coating dispensing system ensures the correct application of coating products.

Mixing systems

Our mixing systems ensure an optimal mixing ratio of two-component lacquers. The correct mixing proportion of 2-component lacquers is the basic requirement for a high quality end product.

Data processing

Data interfaces enable communication between multiple systems. Customized data interfaces can be used to process, analyze and store data from work orders.

Cleaning systems

Our automated cleaning systems are used to clean peripheral equipment in regular cleaning cycles.

Residual waste reduction

By calculating the optimal medium quantity to be applied, this module reduces the amount of residual waste to a minimum. This generates considerable consumption savings.

Consumption calculations

Our consumption calculation systems determine how much material is needed for each job and provide an accurate calculation of the work order.

Colour formulation

We have developed a special solution for our customers to produce their own individual colour mixture. This provides the customer with a wide range of colour tones from the desired colour.

Container manufacturing

We design and manufacture individual tanks according to our customers' specifications.

Pipe and pipeline construction

From the initial planning to the final assembly, we can provide our customers with products from the pipe and pipeline construction sector. Individually adapted to the customer's specific requirements.

Pumps and mixers

If requested, we can also build pumps and mixing systems for a wide range of applications, in order to convey and mix different types of media.

20 YEARS OF EXPERIENCE

Top quality and excellent service are our tradition.